Chức năng mạng giao tiếp được nâng cấp để xuất và lưu trữ dữ liệu liên quan đến quá trình hàn, cùng với phần mềm toàn diện có thể sử dụng dễ dàng bất kể trình độ kỹ năng của người vận hành.

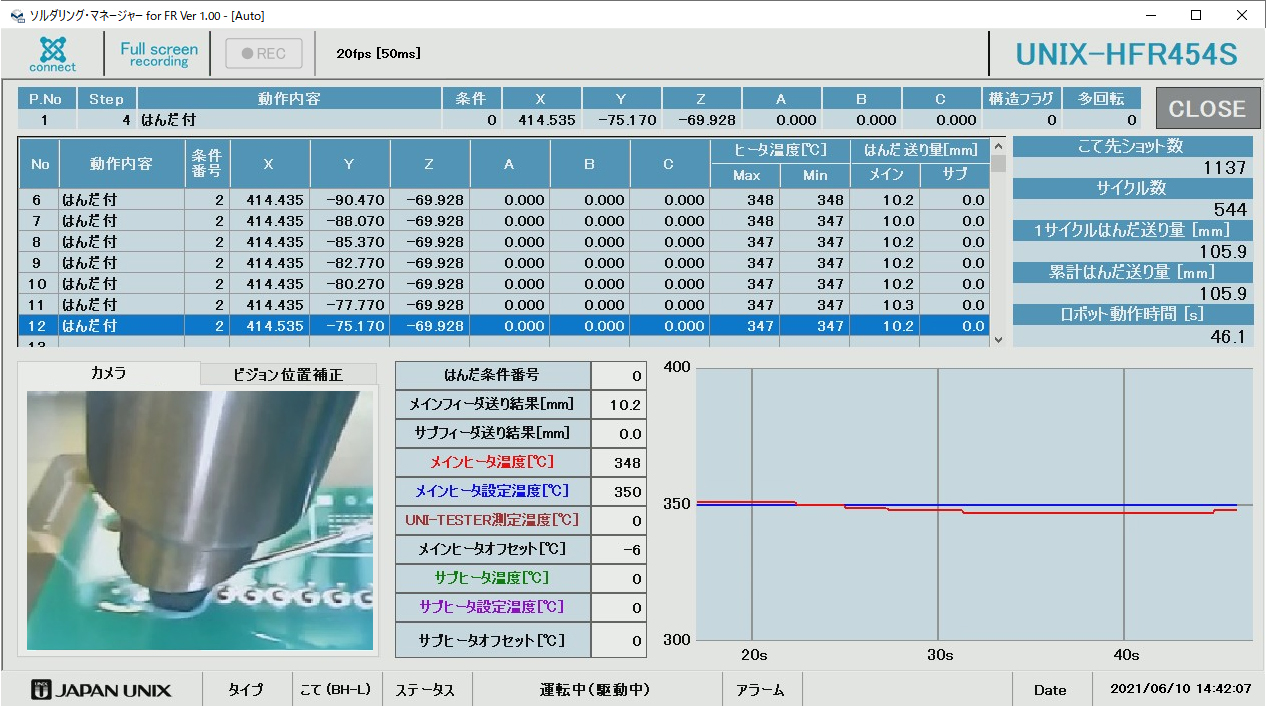

Tất nhiên, thiết bị cũng tương thích với SolderingManager nhằm nâng cao khả năng truy xuất nguồn gốc.

Robot mới được thiết kế để tiết kiệm nhân công hơn và dễ sử dụng hơn.

Với chuyển động đặc biệt của robot nhiều khớp theo phương thẳng đứng, quá trình hàn không chỉ được thực hiện trên bề mặt nằm ngang, mà còn có thể thực hiện trên các bề mặt nghiêng từ các góc tối ưu. Nhờ đó, khả năng sản xuất linh hoạt hơn đã trở thành hiện thực.

Bên cạnh lợi ích về khả năng hàn 3D, robot này còn giúp giảm diện tích lắp đặt. Kích thước và cách thức di chuyển của robot nhỏ gọn hơn nhiều so với robot nhiều khớp ngang. Bộ cơ cấu tùy chọn điều chỉnh vị trí đầu mũi hàn theo 3 trục cũng có thể được lắp theo chiều dọc, giúp tận dụng không gian lắp đặt như một không gian 3 chiều.

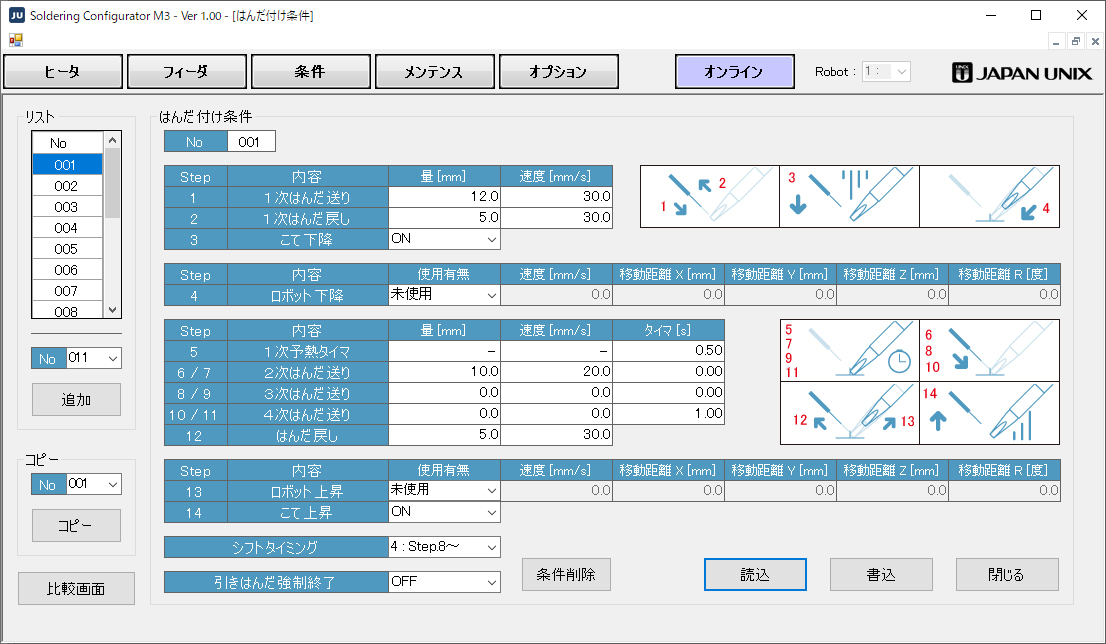

Phần mềm giúp lưu và chỉnh sửa dữ liệu hàn. Giao diện trực quan, cho phép người dùng chỉnh sửa từng bước trên máy tính cá nhân, dễ sử dụng ngay cả với người không có kỹ năng chuyên sâu.

Cho phép theo dõi thời gian thực và truy xuất trạng thái hoạt động của robot hàn. Có thể giám sát liên tục tình trạng sản xuất ngay cả trong dây chuyền in-line, giúp giảm nhân công. Camera gắn trên đầu hàn cũng có thể ghi lại video, kết hợp với mã 2D để truy xuất nguồn gốc chính xác.

Giao tiếp Ethernet cho phép giám sát, truy xuất dữ liệu vận hành và chỉnh sửa từ xa các điều kiện hàn. Nhờ đó, có thể chỉnh sửa điều kiện từ một giao diện chuyên biệt cho từng dây chuyền, hướng tới xây dựng một hệ thống tự động hóa tích hợp cao.

Cũng hỗ trợ giao thức Ethernet công nghiệp (Ethernet/IP).

Đánh giá Rôbốt hàn nhiều mối nối UNIX-FR Series (Verticle)

Bạn chưa đánh giá sao cho sản phẩm này

Đánh giá ngay