Neji Taro aligns screws!

The work efficiency of a production line will be dramatically improved.

● A single unit can handle different screw diameters by changing rails.

・ 8 screw diameters for the manual operation type, 6 screw diameters for the automatic assembly machines

● It feeds screws quickly; 120 screws per minute at average / M3 x 8

(for automatic assembly machines)

● Compatible with the suction type (for automatic assembly machines)

Specifications:

| Power Supply | Input | AC100V ±5% (50/60Hz) |

| Output | DC12V 500mA | |

| Weight(g) | About 3kg (including the rail) | |

| Screw capacity | 80cc | |

| Over load protection circuit | Reverse rotation when overloaded, Forward rotation when restored | |

| Model Number | HSⅢ-10 (M1.0) HSⅢ-12 (M1.2) HSⅢ-14 (M1.4) HSⅢ-17 (M1.7) HSⅢ-20 (M2.0) HSⅢ-23 (M2.3) HSⅢ-26 (M2.6) HSⅢ-30 (M3.0) |

|

| External Dimensions(mm) | 123(W)×181(D)×145(H) | |

| Driver type | For manual operation | |

| Accessories | 1 installed standard rail, 1 guide plate, 1 hexagonal wrench (width across flats 2mm), 1 gauge plate (0.35mm) |

| Model | ||||||

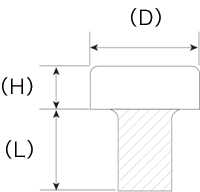

| Feeder Unit only | Feeder Unit (with rail unit) | Rail unit only | Nominal screw diameter | (D) Head diameter(∅) | (H) Head thickness(mm) | (L)Shaft length(mm) |

| HSIII-300 | HSⅢ-10 (with HS-SR10) | HS-SR10 | M1.0 | 1.8-4.5 | 0.35-1.0 | 1.6-10 |

| HSⅢ-12 (with HS-SR12) | HS-SR12 | M1.2 | 1.8-4.5 | 0.35-1.0 | 1.9-10 | |

| HSⅢ-14 (with HS-SR14) | HS-SR14 | M1.4 | 2.0-4.5 | 0.35-1.0 | 2.2-10 | |

| HSⅢ-17 (with HS-SR17) | HS-SR17 | M1.7 | 2.5-4.5 | 0.35-1.0 | 2.7-10 | |

| HSⅢ-20 (with HS-SR20) | HS-SR20 | M2.0 | 3.0-6 | 0.35-4.5 | 3.2-20 | |

| HSⅢ-23 (with HS-SR23) | HS-SR23 | M2.3 | 3.3-6 | 0.35-4.5 | 3.7-20 | |

| HSⅢ-26 (with HS-SR26) | HS-SR26 | M2.6 | 3.6-6 | 0.35-4.5 | 4.2-20 | |

| HSⅢ-30 (with HS-SR30) | HS-SR30 | M3.0 | 4.0-6 | 0.35-4.5 | 4.8-20 |

Reviews Screw Feeder HSⅢ For manual operation (8 Models in Total: HSIII-30, HSIII-26, HSIII-23, HSIII-20, HSIII-17, HSIII-14, HSIII-12, HSIII-10)

Bạn chưa đánh giá sao cho sản phẩm này

Đánh giá ngay