In the ever-evolving landscape of manufacturing and electronics, automation continues to play a pivotal role. The UNIX-DF Series soldering robots from Japan Unix represent a significant leap forward in automated soldering technology. These robots bring numerous advantages to the table, making them an invaluable asset for businesses seeking to enhance efficiency, precision, and overall productivity.

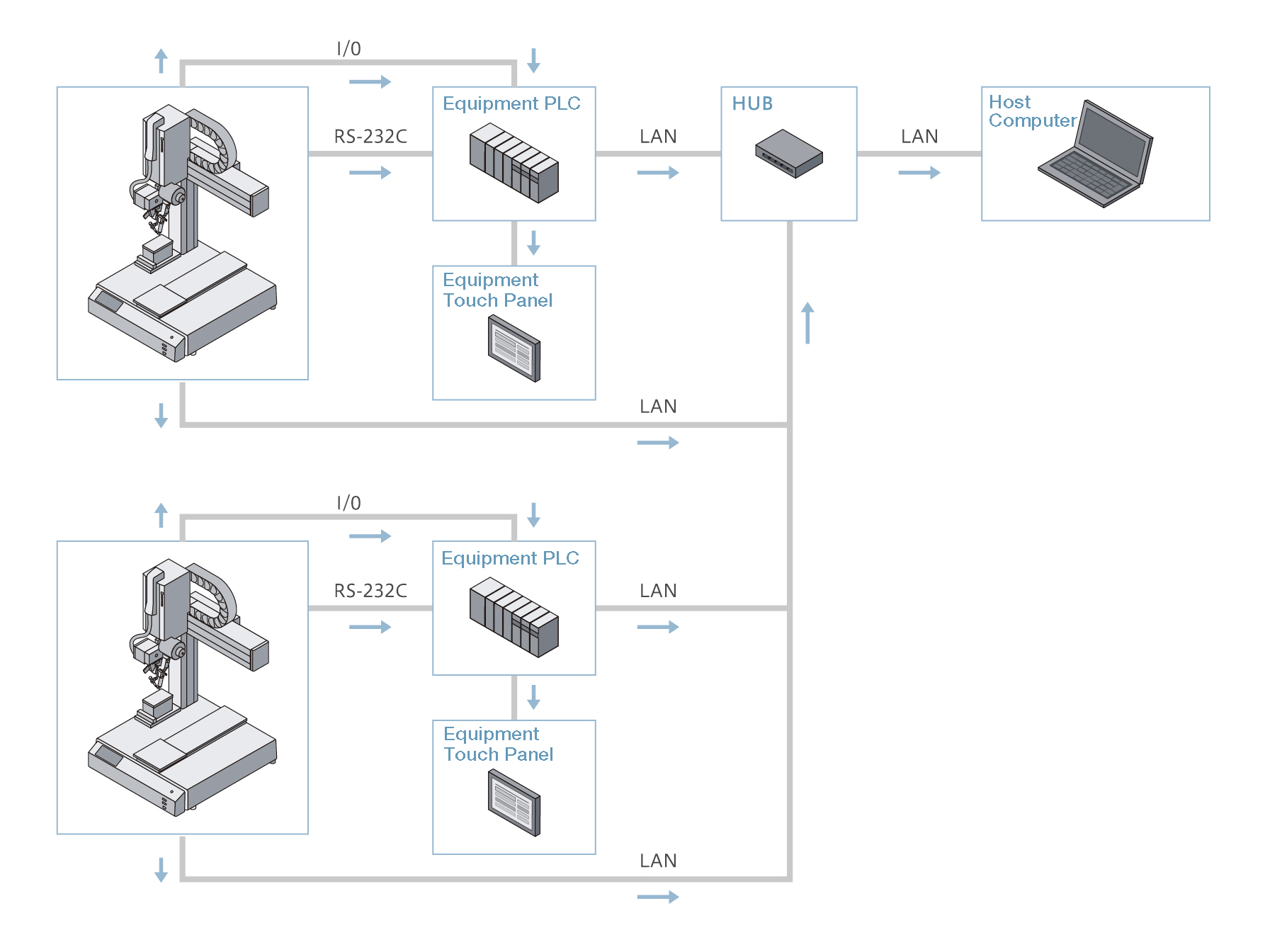

1. Enhanced Network Functionality and IoT Integration

The UNIX-DF Series is designed with Industry 4.0 and IoT in mind. These soldering robots can connect seamlessly to networks, allowing real-time visualization of each soldering process and result. This connectivity facilitates better monitoring, data collection, and quality control, ensuring that manufacturers can maintain high standards and quickly address any issues that arise.

2. Optimized for Various PCB Sizes

Available in three types, the UNIX-DF Series can accommodate different PCB sizes, making it versatile and adaptable to various production requirements. Whether you're working with small or medium-sized PCBs, these robots provide the flexibility needed to handle diverse projects.

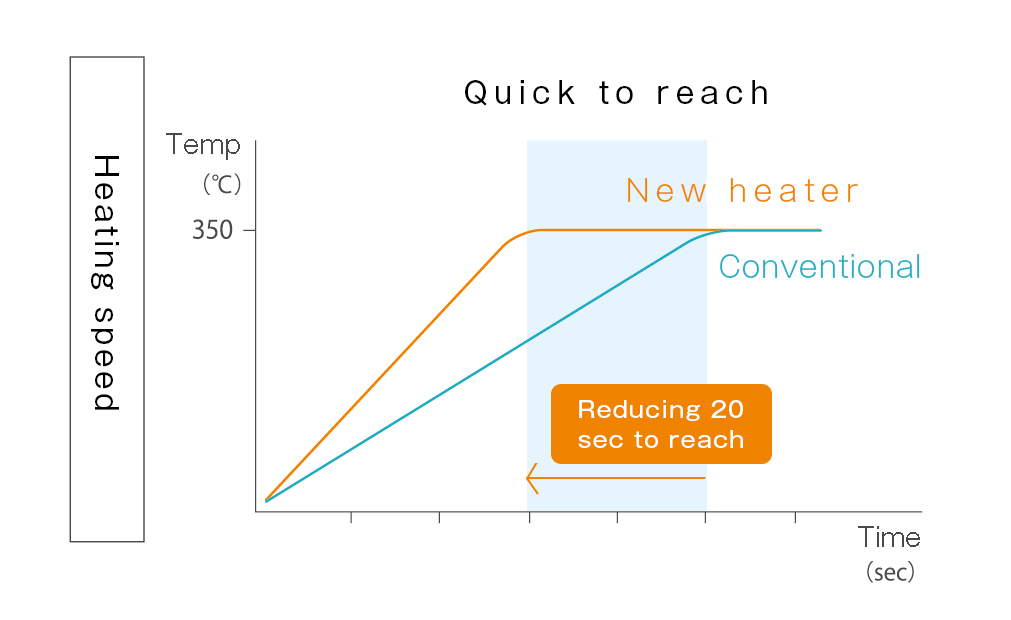

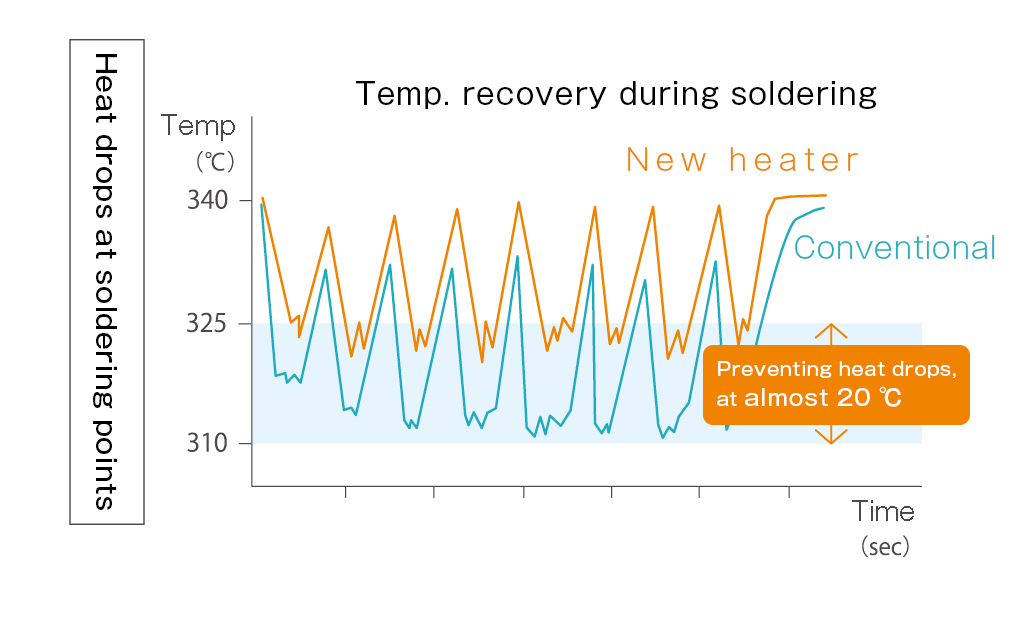

3. Improved Heater and Soldering Mechanism

The series features a new and improved heater that significantly enhances the heating and soldering mechanism. This improvement leads to more consistent solder joints and reduces the risk of defects, which is crucial in maintaining the integrity and reliability of electronic components.

4. High-Speed Operation

With impressive speed capabilities—X, Y axis upto 900mm/sec and Z axis upto 400mm/sec—the UNIX-DF Series ensures rapid and efficient soldering processes. This high-speed operation is complemented by increased rigidity, allowing for faster processing without compromising accuracy or quality.

5. Built-in Soldering Controller

The UNIX-DF Series robots come equipped with a built-in soldering controller, streamlining the setup and operation process. This integration reduces the need for external components and simplifies the overall system, making it more user-friendly and easier to maintain (applicable to UNIX-DF304S and UNIX-DF404S).

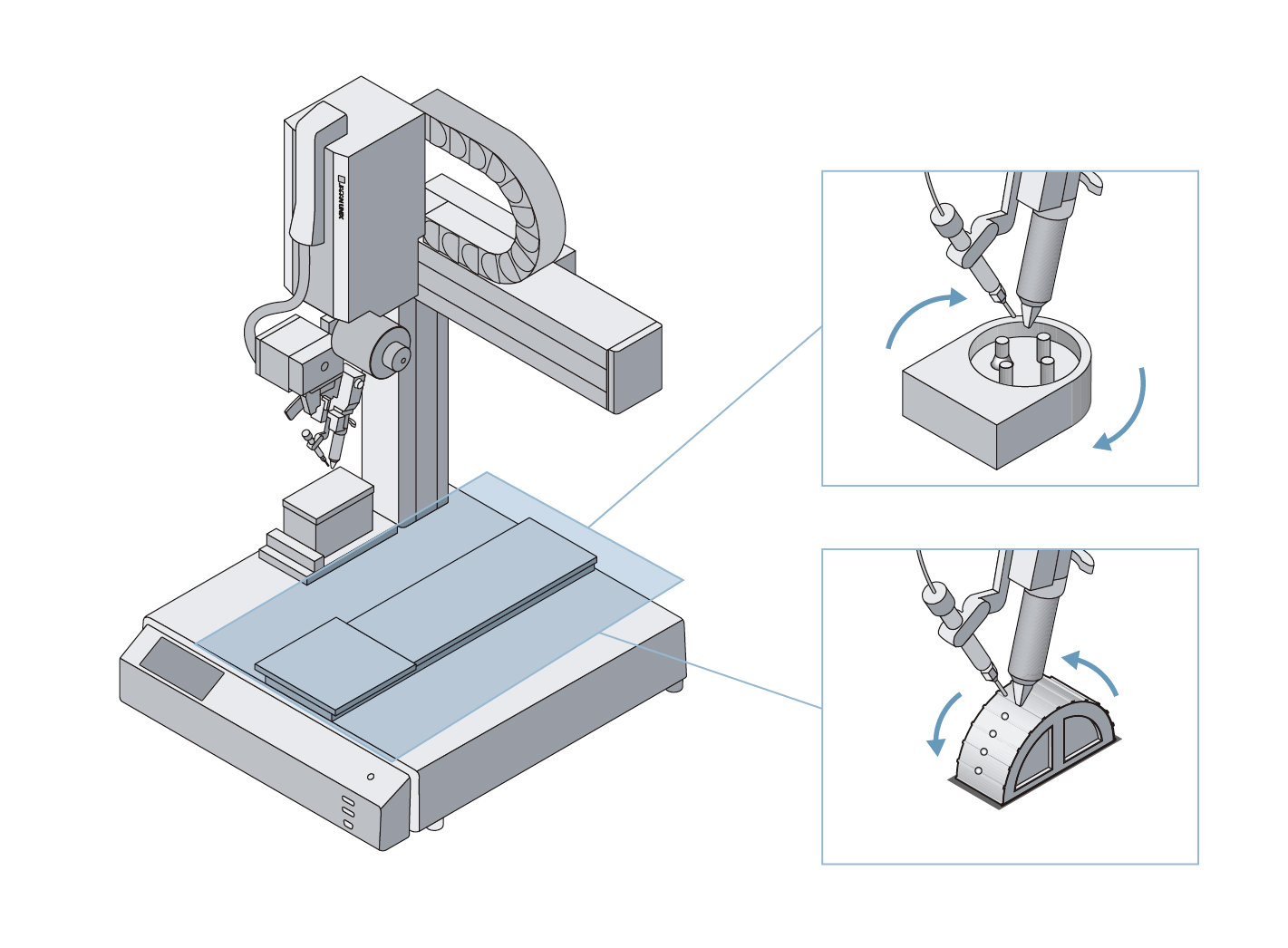

6. Two Additional Axes for Complex Soldering

One of the standout features of the UNIX-DF Series is the inclusion of two additional axes. These axes facilitate penetration angles and enable the rotation of PCBs, allowing for the soldering of components that were previously challenging or impossible to reach. This capability is particularly beneficial for complex and densely packed PCBs.

7. Support for Laser Soldering Systems

The UNIX-DF Series is fully compatible with laser soldering systems. This compatibility expands the range of applications and provides manufacturers with more options to tailor their soldering processes to specific needs, whether they require traditional or laser-based soldering techniques.

8. Environmental and Cost Benefits

Automation with the UNIX-DF Series robots not only improves efficiency and quality but also contributes to cost savings. By reducing the need for manual labor and minimizing the occurrence of soldering defects, manufacturers can achieve significant reductions in production costs. Additionally, the robots' precision reduces waste and the need for rework, further contributing to environmental sustainability.

Conclusion

The UNIX-DF Series soldering robots by Japan Unix offer a comprehensive solution for modern manufacturing challenges. With advanced network functionality, high-speed operation, and the ability to handle complex soldering tasks, these robots are set to revolutionize the soldering process. By integrating the latest technological advancements, the UNIX-DF Series ensures that manufacturers can achieve higher productivity, superior quality, and greater flexibility in their production lines. For businesses looking to stay ahead in the competitive electronics industry, investing in the UNIX-DF Series is a strategic move towards a more efficient and sustainable future.