Làm sạch kem hàn và chất trợ hàn trong các lỗ và trên bề mặt của khuôn in.

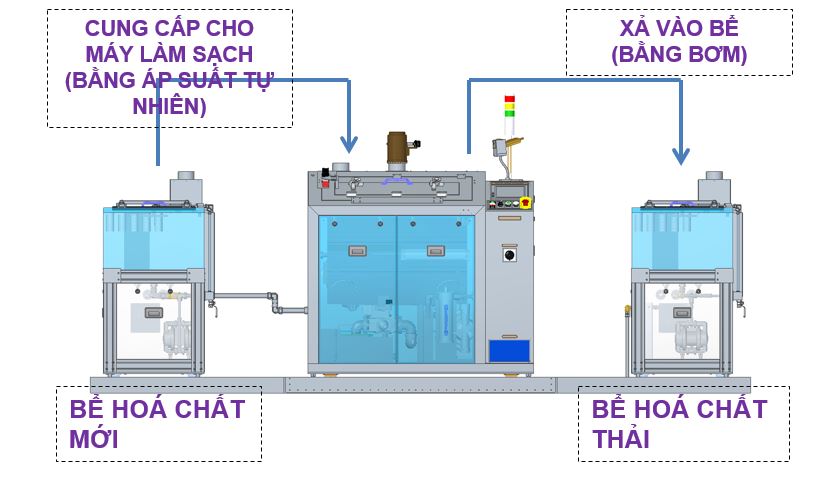

- Hệ thống tái chế chất lỏng

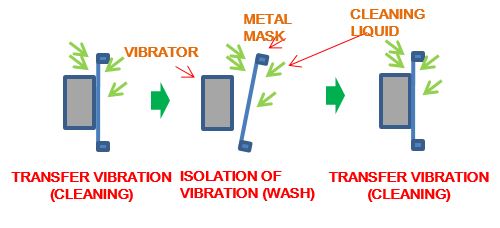

CHU KỲ LÀM SẠCH

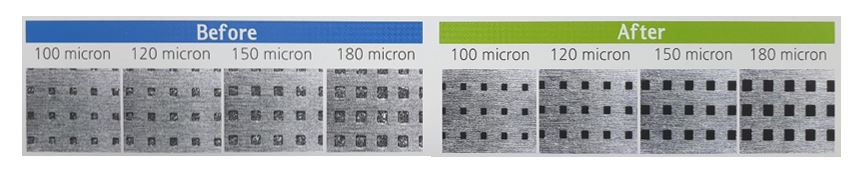

HIỆU SUẤT LÀM SẠCH

HỆ THỐNG AN TOÀN

Cửa sẽ bị khóa và không thể mở trong quá trình vận hành. Còi báo sẽ kêu khi cửa bị mở.

Cảm biến phát hiện rò rỉ bên trong.

Máy dừng hoạt động và còi báo sẽ kêu khi phát hiện có rò rỉ.

Phát hiện khi nắp được mở trong quá trình hoạt động.

Còi báo sẽ kêu sau khi máy dừng khi nắp được mở.

Dừng khẩn cấp.

Nhấn công tắc để tắt nguồn.

Phát hiện hoạt động của cảm biến mực nước trong bình tái chế.

Còi báo sẽ kêu khi mực nước bất thường.

Phát hiện áp suất khí nén.

Còi báo sẽ kêu khi áp suất thấp.

HỆ THỐNG KIỂM SOÁT DUNG DỊCH LÀM SẠCH [BÌNH PHỤ]

MÁY SẤY - TÙY CHỌN

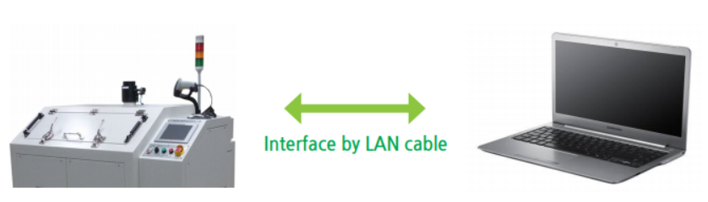

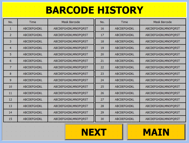

HỆ THỐNG QUẢN LÝ MÃ VẠCH - TÙY CHỌN

Phần mềm quản lý mã vạch

|

Nội dung |

Thông số kỹ thuật |

||

|

JK-MC650ST |

JK-MC740 |

JK-MC650ST-W |

|

|

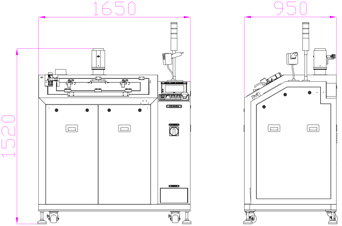

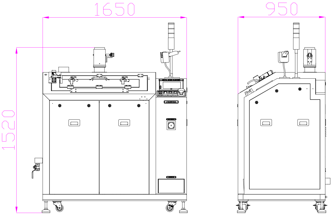

Kích thước và trọng trượng |

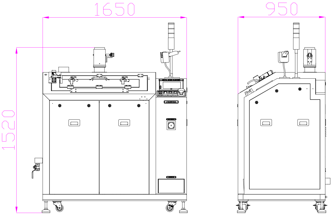

1,650(W) x 950(L) x 1,520㎜(H) |

1,475(W) x 1,095(L) x 1,519㎜(H) |

1,650(W) x 950(L) x 1,520㎜(H) |

|

Phương pháp làm sạch |

Rung siêu âm + Phun (Thanh vòi phun di chuyển trái/phải) |

||

|

Phương pháp sấy |

Phun khí nén vào mặt trước và mặt sau của khuôn in (Thanh vòi phun cố định) |

||

|

Mục tiêu làm sạch |

Mặt nạ kim loại ( 650 x 550㎜ ) |

Mặt nạ kim loại ( 736 x 736㎜ ) |

Mặt nạ kim loại ( 650 x 550㎜ ) |

|

Thể tích bể chứa |

Cao nhất : 60 Lít, Thấp nhất : 40 Lít |

||

|

Trình tự |

Làm sạch → Sấy khô |

||

|

Phương pháp lọc |

Thoát nước: Bộ lọc túi (10 micron), Đầu vào bơm: Bộ lọc lưới SUS, Đầu ra bơm: Bộ lọc gió vi mô (1 micron) |

||

|

Bơm dung dịch làm sạch |

Bơm màng khí nén |

||

|

Hệ thống xả |

Φ98(W) x 50㎜(H) / 2 cổng ( 2.355 CMM(Tiêu chuẩn : 5m/s) ) |

||

|

Áp suất cung cấp khí nén |

5㎏/㎠ - 6㎏/㎠, 800Lít/phút, 2 cổng |

||

|

Nguồn điện |

1 pha 220VAC, 3.1kW, 50/60Hz |

||

|

Độ ồn |

Dưới 75dB |

||

|

Chất liệu / Màu sắc của máy |

SUS ( Thép không gỉ ) / Sơn màu trắng |

||

|

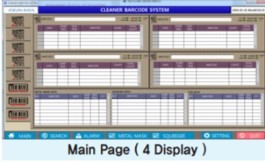

Điều khiển |

Điều khiển PLC + HMI + Bảng điều khiển |

||

|

Quản lý bộ đếm |

Số lần sử dụng, thời gian thay thế bộ lọc, thời gian thay thế dung dịch |

||

※ Quy cách trên có thể thay đổi không báo trước vì mục đích cải tiến sản phẩm.

JK-MC650ST JK-MC740

JK-MC650ST-W

Đánh giá Máy vệ sinh Stencil JK-MC ST Series

Bạn chưa đánh giá sao cho sản phẩm này

Đánh giá ngay